One of the most important metrics in civil engineering and building is the compressive strength of concrete, which indicates how much pressure the material can bear before breaking or significantly deforming. The 28-day compressive strength test is a basic and widely recognized technique for ensuring the structural integrity and durability of concrete structures, among other procedures and tests. The purpose of this article is to investigate the reasoning behind the 28-day timetable, the significance of the test, and the consequences that pertain to the real world, with a particular emphasis on its practical use in building projects.

Understanding Concrete’s Curing Process

Hydration is the process by which the cement particles react with water to produce a hard matrix that binds the aggregates together. This is what makes concrete, a composite material composed of water, aggregate (gravel, sand, or rock), and cement, work. For an extended period of time, this chemical reaction, which is referred to as hydration, occurs, which contributes to the concrete’s rising strength. The rate of strength gain is rapid initially but gradually decreases over time.

The Significance of the 28-Day Mark

Based on the hydration kinetics of the concrete and practical concerns, the 28-day mark is not arbitrarily set. This is why it’s important:

Standardization: Concrete batches and mixes can be compared in terms of their quality and strength using the 28-day compressive strength test, which provides a standard basis for comparison. Because it is a universally recognized standard, it facilitates consistency in performance for engineers and construction industry experts.

Optimal Hydration Point: Research and empirical evidence suggest that concrete achieves approximately 70-75% of its compressive strength within the first 7 days, reaching near 90-95% by the 28th day. This period allows for a significant portion of the hydration process to complete, giving a reliable indicator of the concrete’s long-term performance.

Practicality in Construction Scheduling: The 28-day period strikes a balance between the need for early strength gain (to proceed with construction activities) and the practicality of waiting for the concrete to develop sufficient strength for its intended load-bearing role.

The Process and Importance of Compressive Strength Testing

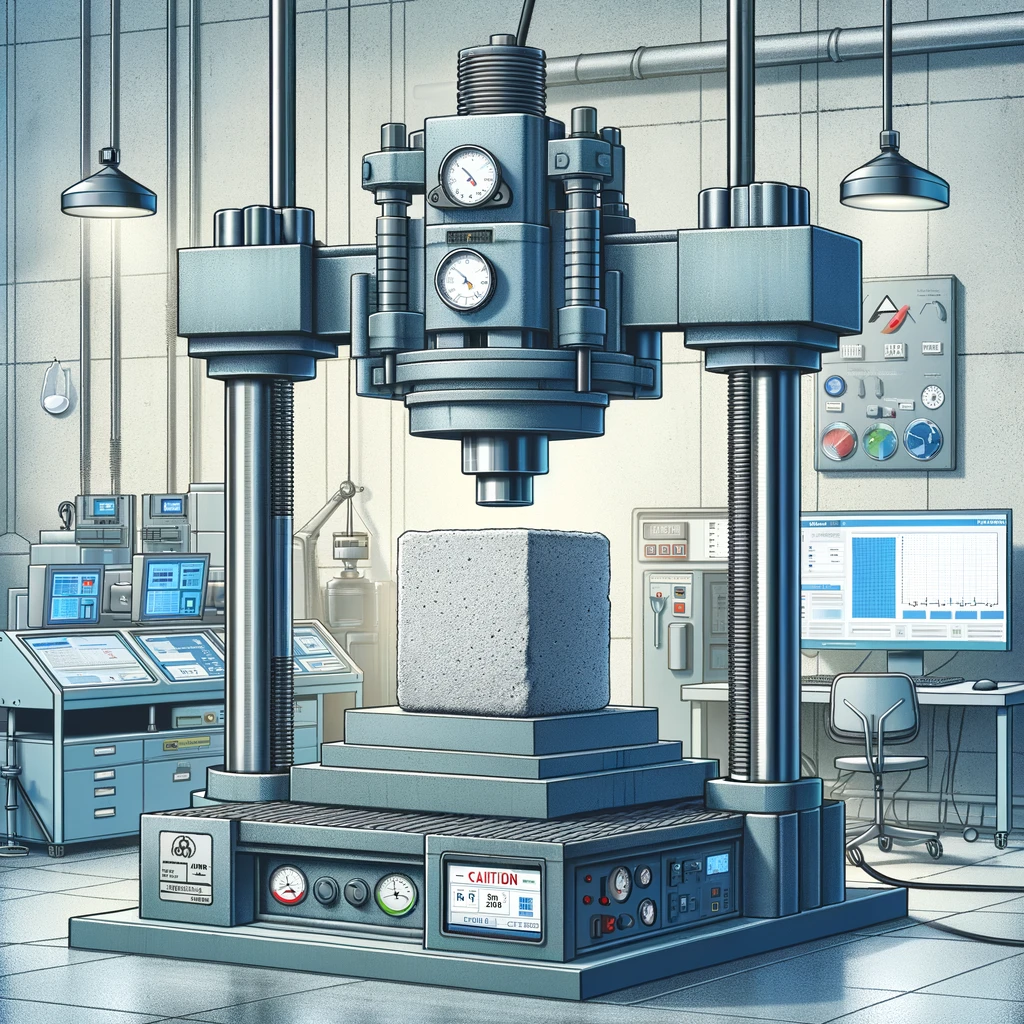

Compressive strength testing involves subjecting concrete samples, typically cylinders or cubes, to a progressively increasing load until failure occurs. This test helps in determining the maximum load the concrete can withstand, which is crucial for:

Ensuring Compliance with Design Specifications: It verifies that the concrete used in construction meets the strength requirements specified in the design, ensuring the structural integrity and safety of the building or infrastructure.

Quality Control and Assurance: Regular strength testing as part of quality control processes helps in identifying issues with the concrete mix or curing conditions early, allowing for timely interventions.

Predicting Long-term Performance: The 28-day strength test serves as a reliable predictor of concrete’s long-term performance under service loads, environmental conditions, and other factors affecting durability.

Example and Practical Insights

Consider the construction of a multi-story residential building where concrete slabs are used for the floors. The design specifies a 28-day compressive strength of 35 MPa (MegaPascals) to ensure the slabs can support the anticipated loads, including furniture, occupants, and internal walls.

After pouring the concrete for a floor slab, samples are taken and cured under controlled conditions. On the 28th day, these samples are tested for their compressive strength. If the test results meet or exceed 35 MPa, it confirms the concrete mix was correctly formulated and cured, ensuring the slab’s structural integrity and safety. If the results are below the required strength, it triggers a review of the concrete mix, curing practices, or even structural reassessment.

Finally, there is no better way to determine whether concrete is suitable for its intended structural duty than using the 28-day compressive strength test. It is a mix of scientific theory and practical necessity that makes sure buildings are safe and last a long time. Civil engineers and construction experts use this crucial test to ensure our built environment lasts for centuries. If you have any question regarding this please comments below.