Glass Fiber Reinforced Concrete

Glass fiber reinforced concrete is an engineered material composed of the same ingredients required in the production of the concrete with the addition of the reinforcement of glass fiber in the concrete. GFRC comprises tiny discrete fibers that are consistently spread and haphazardly oriented. Initially, the use of glass fiber in the concrete was threatened because of the alkaline nature of both made it difficult to exist again the corrosion. The problem was solved by the use of anti-alkaline glass fiber.

Glass fiber reinforced concrete (GFRC) is a material that is building a substantial influence on the economics, technology, and aesthetics of the building industry worldwide for over 40 years. GFRC is one of the most multipurpose structure tools obtainable to architects and engineers Compared to old concrete, it has composite properties because of its unusual structure. Diverse constraints in the GFRC such as water-cement ratio, porosity, composite density, inter filler content, fiber content, orientation, and length influence properties and behavior of GFRC as well as the accuracy of the production method.

Properties of Glass Fiber Reinforced Concrete

The properties of Glass Fiber Reinforced Concrete are dependent on the structure of the composite. The properties of the GFRC are the function of the concrete and anti-alkaline fiber used for the preparation. And then one needs to study the interaction of both-glass fiber and concrete. So, the structural properties of GFRC are all about the concert and fiber.

- For the concrete, Glass fiber reinforced concrete mortars are typically applied in the thin pane which is working mainly for covering. In these applications, the fibers act as the primary reinforcement and their content is usually in the range of 5–15 % by volume.

- For the fibers, there are two types of reinforcing; 3D and 2D. In the 2d GFRC, the level of fiber reinforcing is very incompetent, demanding very high loads of fibers. Naturally, only about 15 % of the fibers are leaning correctly. In 2d GFRC, The fibers are oriented haphazardly within a thin plane. As the fibers are scattered into the forms, they lay flat, settling to the shape of the form.

The effect on the mechanical properties of the concrete after the reinforcement of fiberglass can be categorized and summarized as shown in the table below.

| No# | Mechanical properties | Change |

| 1 | Compressive Strength | Due to reinforcement of fiber in the concrete, compressive strength increase. |

| 2 | Modulus of Elasticity | No important effect of use GFRC. |

| 3 | Stress–Strain Curve | Highly effected |

| 4 | Flexural Strength | Glass fiber increases the flexural strength of concrete. |

The effect of the glass fiber reinforcement concrete on the physical properties of the structure is also undeniable.

| No# | Physical properties | Effects/ Change |

| 1 | Creep | The chances of cracking increases. |

| 2 | Porosity | There are several micro-pores in the concrete. Special consideration must be applied during reinforcement of the fiber |

| 3 | Chloride Penetration Resistance | Increase in the fiber content increases the chlorine resistance. |

| 4 | Electrical Resistivity | Can decrease. |

Ingredients of Glass Fiber Reinforced concrete

Glass Fiber Reinforced concrete has the reinforcement of the glass fiber in the concrete. Glass Fiber Reinforced Concrete is, well, pretty much exactly what it sounds like: concrete reinforced with glass fibers. As in most composite ingredients, the fiber elements in GFRC can be wisely oriented, or casually distributed, in the solid matrix. So for the preparation of the GFRC, one has to start from the preparation of the concrete, and after there will be the spray of glass fiber on it. For the concrete, cement, sand or other aggregate and water is required. The fiber for the concrete is added about 4% to 6% by weight.

Applications of Glass Fiber Reinforced

Glass Fiber Reinforced concrete has been using in the various fields of life including industrial, medical textile, manufacturing, and building industry. GFRC has compound properties as paralleled to old concrete, because of its special structure. As a result of the structural properties, it has appropriate decoration, sturdy and durable structure. Moreover, because of being fast to connect and easy to handle and transport, it provides low cost.

It scatters or absorbs sound and it is environmentally friendly Can be used for the noise control, GFRC can be used as the noise barrier; thick fiberglass in the concrete does not allow the noise to pass through it. In the Architectural industry, GFRC panels provide good aesthetics and high resistance to weathering and the fire and therefore very much suitable for the durability of the structures. Complex freeform architecture is one of the most striking trends in contemporary architecture. More resistance of the GFRC to the strains makes it usable in the interior of the houses.

Advantage of GFRC

- GFRC’s service life is higher than traditional concrete

- High–efficiency.

- Environmentally–friendly,

- Cost–effective and building technology.

- Flame resistant.

- Resistant to strains

- Resistant to fire

- GFRC does not require any extra reinforcement.

- 50–70 % lighter than traditional concrete

Disadvantages of GFRC

- It is difficult to self–mix (requirement of special material)

- Its cost is higher than that of traditional concrete.

- Ductility is not available in the GFRC.

Video Of making GFRC-Glass Fiber Reinforced Concrete

GFRC is one of the most multipurpose structure materials accessible to architects and engineers. It has added meaningfully to the economics, technology, and aesthetics of the building industry. Glass fiber reinforcement in the concrete makes it versatile in the use.

The use of GFRC is not new; its demand is increasing day by day. Sharing the good information is the virtue so keep sharing it.

You can also read

Spalling Bricks : Spalling Brick Cause and Repair

Spalling Concrete: Spalling Concrete Causes ,prevention and Repair

Reference and Related Research:

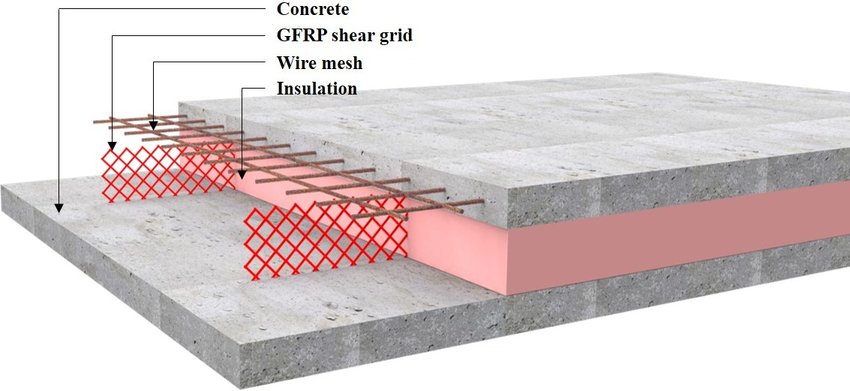

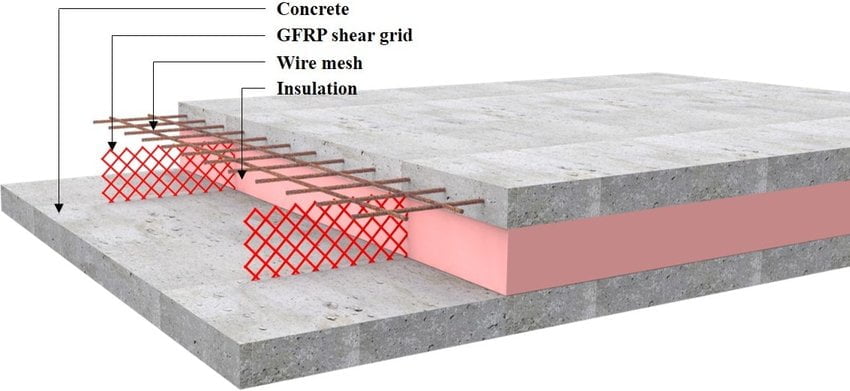

1.Kim, Junhee & You, Young-Chan. (2015). Composite Behavior of a Novel Insulated Concrete Sandwich Wall Panel Reinforced with GFRP Shear Grids: Effects of Insulation Types. Materials. 8. 899-913. 10.3390/ma8030899.

2.Harle, Shrikant. (2014). COMPARISON OF GLASS FIBER REINFORCED CONCRETE & GEOPOLYMER CONCRETE WITH GLASS FIBER REINFORCEMENT. International Journal of Research in Engineering and Technology. 03. 263-265. 10.15623/ijret.2014.0301045.

3.https://www.slideshare.net/bhavinshah80/glass-fiber-reinforced-concrete-53784748

4.Toutanji, H. A., & Saafi, M. (2000). Flexural behavior of concrete beams reinforced with glass fiber-reinforced polymer (GFRP) bars. Structural Journal, 97(5), 712-719.

5.Beaudoin, J. J. (1990). Handbook of fiber-reinforced concrete. Principles, properties, developments and applications.

6.Benmokrane, B., Wang, P., Ton-That, T. M., Rahman, H., & Robert, J. F. (2002). Durability of glass fiber-reinforced polymer reinforcing bars in concrete environment. Journal of Composites for Construction, 6(3), 143-153.

7.De Luca, A., Matta, F., & Nanni, A. (2010). Behavior of full-scale glass fiber-reinforced polymer reinforced concrete columns under axial load. ACI Structural Journal, 107(5), 589.

8.Shah, S. P., Ludirdja, D., Daniel, J. I., & Mobasher, B. (1988). Toughness-durability of glass fiber reinforced concrete systems. ACI Materials journal, 85(5), 352-360.

9.Kizilkanat, A. B., Kabay, N., Akyüncü, V., Chowdhury, S., & Akça, A. H. (2015). Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Construction and Building Materials, 100, 218-224.

10.https://journals.sagepub.com/doi/10.1177/0731684405058273

11.https://www.rnbco.org/glass-fiber-reinforced-concrete-gfrc/

Thank you for explaining Glass fiber reinforced concrete is an engineered material comprised of the same ingredients needed in the production of the concrete, with the addition of the reinforcement of glass fiber in the concrete. My friend is building a property, and he wants to try GFRP assemblies for the building’s construction materials. I must advise him to go for it since it’s a good alternative to steel and timber.