Welcome to Howtocivil. In this article, you are going to learn about the concrete definition, types, function, Ingredients, grade, manufacture and curing time, and everything you need to know about concrete. Hope you enjoy this article.

Concrete Definition

Concrete can be defined as the composite material composed of the binding medium such as the mixture of cement, water, and different fine and coarse aggregates. Many people do consider cement as concrete, but cement is just a part of concrete. Concrete structures that have been built around the world are subject to a wide range of different conditions of use and acquaintance to environmental conditions comprising erosion, weather, and pollution.

All environmental conditions found concrete as the long-lasting and the best binding material. Besides whatever the conditions might be, concrete is expected to provide satisfactory performance for the wholeness of their service life with very little care. I think you understand, what is concrete now. If you then you continue reading to next topic ” Concrete ingredients or what concrete made of“.

Concrete ingredients Or what concrete made of

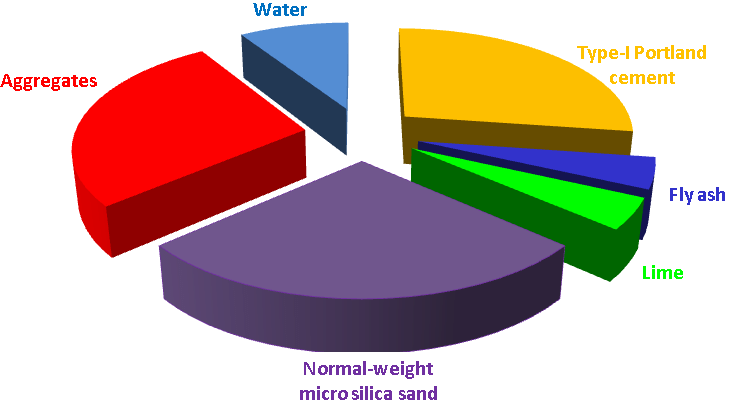

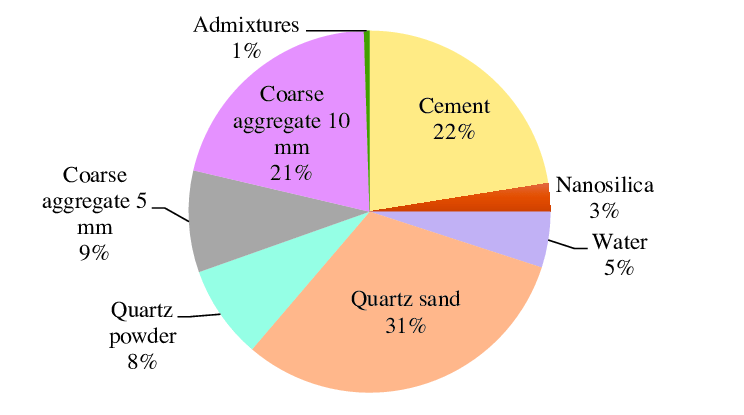

What makes the monster so much rigid, long-lasting, and powerful enough to support every condition? To answer this, one has to look into the ingredients of concrete. This composite material is composed of various ingredients. The properties and functions of this binding material depend upon its constituents. If the constituents have more strength, then concrete will be more sustainable. Have a look at concrete ingredients:

Concrete = Filler (Aggregates)+ Binder (Cement)+Water +Admixture (Optional)

Binding materials

In concrete, Portland cement is generally used. It gives strength and its selection is a function of concrete durability and functioning. According to the American Society for Testing and Materials (ASTM) there are five types of cement, but in the manufacturing of concrete Type I. Type III cement is used maximum time.

Aggregate

The aggregates usually comprise 75% volume of the concrete. This percentage might give you the importance of these aggregates. One must be very careful in the selection of aggregates because the property of aggregates is basically the property of concrete. These are granular materials such as sand, gravel, crushed stone, or iron-blast furnace slag. Fine aggregate is usually the sand and all other materials that pass through sieve #4 [0.187 in. (4.75 mm). On the other hand, coarse aggregates are the stones, gravel, and all other material that is retained on the #4 sieve.

Water

Water is one of the most important ingredients of concrete. Because of water, the hardening of concrete through a process call hydration happens. When you going to make concrete you need to use pure water otherwise it can make weak concrete, also make a disturbance in the hydration process. You should also consider the water-cement ratio, too much water reduces concrete strength, and too title water will make concrete unworkable.

Admixtures

Admixtures are added to give extra power and increase the toughness, resistance, rigidness of the concrete. There are admixtures that reduce the viscosity, increase the resistance. Some have the ability to delay the setting time when necessary

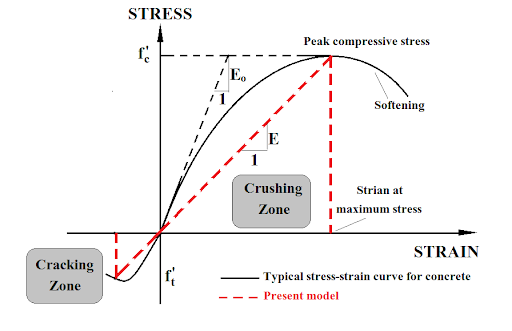

Strength of concrete:

The strength of concrete can be known by knowing the compressive strength of this material. The compressive strength of any material is the property of a material to withstand against the provided load without any blows or crushes.

Concrete compressive strength varies from 15Mpa to 35Mpa and it depends upon several factors like water-cement ratio, types of admixtures used, type of aggregate uses, and type of cement used. Test on strengths revealed that concrete by using good materials have 69Mpa strength at 28 days.

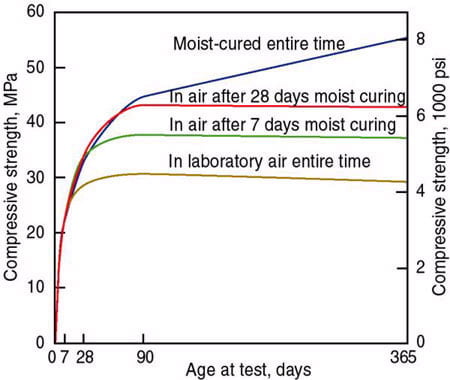

Curing time of concrete:

Curing of concrete is defined as the process of preserving the wetness and temperature circumstances of concrete for hydration response to normally so that concrete develops hardened properties over time. The main components which need to be taken care of curing are moisture, heat, and time during curing the process.

If curing is not done, there is a chance of building cracks in the concrete. However, 28 days are considered to be the best curing time for the 100% strength of concrete. Concrete develops 69Mpa strength on its 28 days after manufacturing.

| Curing Time | Strength (%) |

| 1Day | 16% |

| 2Days | 40% |

| 7 Days | 60% |

| 14Days | 89% |

| 28Days | 99.9% |

Types of concrete:

There is various type of concrete available in the market based on its functionality, strength and structure. For construction purposes, if someone goes to the market to buy the concrete for his/her building-it is available in two forms:

- Normal mix concrete

- Design mix concrete.

However, on the basis of material used and the construction required and design purpose there are also further three types of concrete.

- Plane cement concrete

- Reinforced Cement concrete

- Pre-stress Cement Concrete

According to binding Material concrete can be classified as

- Cement concrete

- Lime Concrete

Based on Weight, Concrete can be classified into 4 categories they are

- Ultra-Light Weight Concrete

- Light Weight Concrete

- Normal Weight Concrete

- Heavy Weight Concrete

Based on Strength, Concrete can also be classified into Four Categories

- Low-strength concrete

- Moderate-strength concrete

- High-strength concrete

- compressive strength

- Ultra high-strength concrete

Based On Additives

- Normal concrete

- Fiber Reinforced Concrete

- Polyumer concrete

- Ready-Mix Concrete

- Green Concrete

- High-Performance Concrete

- Ultra-High Performance Concrete

- Rapid Strength Concrete

- Shrinkage Compensating Concrete

- Fibre-Reinforced Concrete

- Asphalt Concrete

- Polymer Concrete

- Gypsum Concrete

- Vacuum Concrete

Normal mix concrete:

It is a type of concrete that is prepared according to the specific considerations of design. Common ingredients used here are cement, water, and aggregate. Setting time could be varied from 20 to 80 minutes. If one looks at 28 days formula for concrete, it provides more than 80% strength to concrete which should be more than 95%.

Design mix concrete:

Concrete is not prepared on a hit and trial basis. Ingredients’ ratio is carefully selected after doing a lab test. After performing a different test on the different proportions of material, the best design is selected. Design mix or simply mix designs are prepared according to the strength required for the structure.

Plane concrete construction:

In-plane concrete, there will be no reinforcement. The most common ingredients; cement, aggregate, and water is mixed with proportion 1:2:4 respectively. In an area where less tensile strength is required like pavement and the other small building, plane concrete construction is usually used.

Reinforced concrete construction:

A mixture of cement, sand, coarse aggregate and water with reinforcement is known as Reinforced concrete construction. Here the tensile strength of the structure increases. It is used as a building substantial for nearly all types of buildings such as inhabited concrete buildings, engineering structures, dams, roads, tunnels, multi-story buildings, towers, channels, sidewalks, and superhighways.

Cost of Concrete

The cost of concrete depends upon several factors like quality of material used in concrete, local prices of binding material like cement, and the area for which concrete required. But the thumb rule is that the cost of concrete is $108 per cubic yard. Pouring concrete ranges in price from $8 to $18 per square foot.

Weight of concrete

The unit weight of the concrete varies depending upon the basic constituents used in the manufacturing of concrete. Quantity and thickness of the aggregate, the water, and cement content matter the most in determining the unit weight of concrete. Apart from this, 1 cubic meter of concrete weighs 2400 kg.

Advantages of concrete:

- Ingredients are easily available

- Concrete can easily handled and molder to any desired shape .

- Easy to transported from the place of mixing to place of casting

- The monolithic character of concrete gives it a better appearance and much rigidity to the structure.

- The property of concrete to possess high compressive strength makes a concrete structure more

- Economical than a steel structure.

- More Economical

- Ability to be cast

- More Energy Efficient

- Excellent Resistance to Water

- High-Temperature Resistance

- Fire Resistance

- Aesthetic Properties

- Ability to Consume waste

- Ability to work with reinforcing Steel

Disadvantages of concrete:

- Low Tensile Strength

- Lower Ductility (Brittle)

- Volume Instability

- Formwork is needed

- Low Toughness

- Long Curing Time

- concrete is required to be reinforced to avoid cracks

- Due to drying shrinkage and moisture expansion concrete may crack

Properties of concrete

Freshly mixed concrete should have the following properties

- workability

- segregation

- bleeding

- Harsh

In the harden state of concrete, should have the following properties

- Strength

- Durability

- Impermeability

- shrinkage

- creep

- Thermal expansion

- Modulus of Elasticity

Factors affecting the performance of concrete fresh concrete

- Cement

- Aggregates

- Water cement ration

- Mixing of concrete

- Transporting

- Placing

- Compacting hardened conrete

- Curing

Tests Of concrete

Tests on Fresh Concrete

- Vee-bee consistometer test

- Compaction factor Test

- Slump test

- Air content

- Setting Time

- Segregation resistance

- Unit weight

- Wet analysis

- Temperature

- Heat generation

- Bleeding

Tests on Hardened Concrete

- Compressive strength

- Tensile strength

- Modulus of elasticity

- Permeability Test

Other quality tests are conducted to test the following

- Modulus of rupture

- Density

- Shrinkage

- Creep

- Freeze/thaw resistance

- Resistance to aggressive chemicals

- Resistance to abrasion

- Bond to reinforcement

- Absorption

Concrete proves to be a very good binding material. Its strength can be increased by adding the proper ratio of admixtures. 28 days are the best curing time for the concrete where it gives the optimum strength i-e 100%. Its variability in types depending upon its use in the construction makes it versatile and usable.

Note: I collected the data from my old notes, I performed the various tests in my Uni-life on making concrete by adding some admixtures like ash. I used some reading from that data. Advantages and disadvantages are common I knew it. I was well aware about types and its ingredients.

You can watch this animation demonstration for a better understanding

[epcl_box type=”information”]Reference: [/epcl_box]

Improvement of Concrete Durability by Nanomaterials

Basic Introduction of concrete as a construction Material

Welcome to howtocivil .In this course, You are going to learn concrete definition, types, function, Ingredients, grade, manufacture and curing time, and everything you need to know about concrete. Hope you enjoy this Course.

Course Provider: Organization

Course Provider Name: Howtocivil

Course Provider URL: https://www.howtocivil.com/concrete-a-complete-article/

4.6

It’s great that you talked about concrete and how it comes with cost-effective benefits. Recently, one of my uncles mentioned he’s interested in investing in a construction project. My cousin might need to read about construction materials, so I’ll be sure to share this article with him. Thanks for the information on concrete and how it’s important to select quality materials for a project.

Great article! I found your introduction to concrete as construction material to be very informative and well-written. Concrete truly is a versatile and essential component in the construction industry. I appreciate how you highlighted its durability, sustainability, and cost-effectiveness.

The examples you provided, such as the Hoover Dam and the Burj Khalifa, further emphasize the incredible potential of concrete in creating iconic structures. It’s fascinating to learn about the various types of concrete and their specific uses, like reinforced concrete for high-rise buildings and precast concrete for rapid construction.

Thank you for sharing this valuable information. I’ll definitely keep an eye out for your future posts.