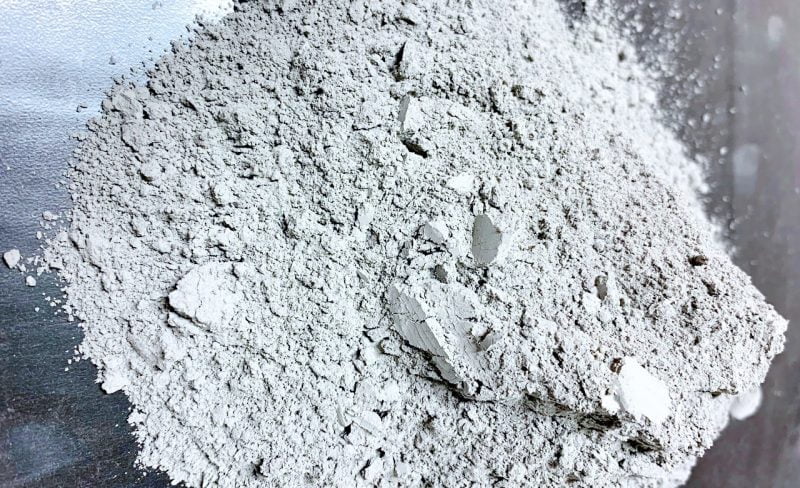

Cement is one of the best binding materials in the construction industry that is used to reinforce the building units such as stones, bricks, tiles. Cement is the finely powdered material that hardens when mixing with water. It is used worldwide in all types of constructions. There are more than 2273 active cement production plants in the world; according to the world cement directory.

Cement usually mentions to a very fine dusty substance primarily made up of limestone (calcium), clay (silicon) or sand, iron ore, and bauxite (aluminum) may include some other admixtures like chalk, shells, shale, marl, clay, slate, blast furnacse slag . The top three producers of Cement in the world are China America and India, where China contributes more than 45% in the cement industry.

What is Cement?

In BS EN 197-1, ‘cement’ is defined as: “ A hydraulic binder, i.e. an excellently crushed inorganic material which, when mixed with water, forms a paste which sets and hardens by means of hydraulic reactions and processes and which, after hardening, retains its strength and stability even underwater.”

“Cement can be defined as the bonding substantial possessing cohesive & adhesive possessions which mark it capable to bond the diverse construction materials and form the compressed unit”.

Simply, in the terms of concrete, “Cement is an adhesive that is used to bind sand and aggregates to make concrete”

History of Cement:

Cement is being used as the binding material throughout history. In earlier, Romans used lime as the cement-binding material. They also used to form the hard mass (cement) by the reaction of the lime with the volcanic ash in the presence of the water. After this, Portland cement was started using after its discovery in 1824.

Joseph Aspdin grabbed out a patent in 1824 for “Portland Cement,” a material he formed by heating finely-ground clay and limestone and ground the mixture until it became powder. He called it Portland cement because the concrete made from it looked like Portland stone, a widely-used building stone in England. Later, in 1845, Isaac Johnson prepared the first new Portland cement by heating a combination of chalk and clay at much higher temperatures, alike to those used now a day.

Cement Manufacturing Flow Chart

Types of cement:

There are various uses of cement in the construction industry. Depending upon the use and strength required, there have been many types of cement developed by the researchers.

1. Ordinary Portland cement (OPC):

This is the most widely used type of cement. It can be used in all constructions where special properties are not required. The common ordinary Portland cement is Portland cement clinker whose performance is alike to Portland cement. It is usually castoff for the reinforced concrete buildings, bridges, pavements, and where soil circumstances are usual.

2. Rapid hardening cement:

As the name indicates, rapid hardening cement is built to gain strength and hardens more quickly. It is quite similar to OPC but the only difference with higher tri-calcium silicate. Its strength is the same in 3 days as of OPC in 7 days.

3. Portland Pozzolana Cement:

Portland pozzolana cement (PPC) is some sort of blended cement that can be created by assimilating the OPC clinker with the gypsum. Fly ash can also be used in the process of manufacturing the PPC.

4. Quick setting cement:

Quick setting cement is required at the construction places, where the quick setting of mortar or concrete is required like on the roads. Quick setting cement can be achieved by adding calcium to the cement.

5. Low Heat Cement:

Low heat cement is specially designed to get the low heat of hydration. This can be achieved by increasing the percentage of C2S and keeping the proportion of C3S by 6%. Low hydration makes the low heat cement to use in the construction of dams, large footings, large raft slabs, and wind turbine plinths.

6. Sulphate Resisting Cement:

Sulphate Resistant Cement is very much resilient to Sulphate outbreaks and is suitable for use in bases near the seashore and canal linings. Sulphate resisting cement can be prepared by upholding C3A level within the definite limit of 3.5%

7. High Alumina Cement:

High Alumina Cement was first industrialized in the United Kingdom in 1925. Alumina Cement is contrived by crushing the clinkers of alumina and calcareous material such as lime by combining or sintering procedure. It can be used in marine construction due to its durability.

8. White Cement:

White Portland cement is prepared by mixing the white aggregates with the ordinary Portland cement. It is prepared by the raw material containing very little Iron Oxide and Manganese Oxide. Its color is very much appealing from the architectural point of view.

9. Air Entraining Cement:

Air entraining cement is the type of cement in which air bubbles have been introduced. It can be used with good results for a variety of conditions. It has been established to yield concrete that is resilient to freeze-thaw action, and to climbing produced by chemicals applied for severe frost and ice removal.

10. Hydraulic Cement:

Hydraulic cement can be used to stop the entrance or flow of the water in the concrete or other structures. It can be used in swimming pools and foundations.

11. Hydrographic cement:

Hydrophobic cement comprises the admixtures which have the ability to decrease the wetness of cement grains. The frost resistance of the hydrophobic cement is very much high as compared to the others due to the uniform distribution of the fine pores.

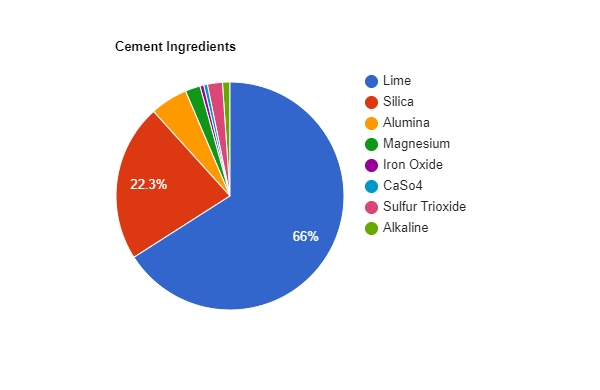

Cement ingredients:

| No# | Ingredients | %in cement | Functions |

| 1 | Lime | 62 | To impart strength, deficiency can decrease the setting time. |

| 2 | Silica | 21 | To impart the strength |

| 3 | Alumina | 5 | To impart the quick setting of the cement |

| 4 | Magnesium | 1-3 | It should not be more than 2%. |

| 5 | Iron oxide | 0.5 | It imparts color to cement |

| 6 | Caso4 | 0.1-0.5 | Can slow down the setting time, present in cement as gypsum. |

| 7 | Sulfur trioxide | 1-3 | The soundness of the cement is due to sulfur trioxide, which should not be more than 2%. |

| 8 | Alkaline | 0-1 | Should not be more than 1%. |

Grade of Cement :

Cement is available in the three grades as grade 33, grade43, and grade 53. These grades measure the strength of the cement and the strength of the cement is measured by the compressive strength. The compressive strength of grade33 cement after the 28 days of setting is 33 Mpa. This type of cement is castoff for general construction work under normal environmental conditions. While the compressive strength of grade43 grade cement after 28 days is 43 Mpa. This type of cement is castoff for plain concrete work and plastering works.

Similarly, the compressive strength of grade53 cement after 28 days is 53mpa. It is used for structural dedications as in reinforced cement concrete. Each cement grade is specific for its use; the use of cement grade for every type of construction can affect the structure’s durability and strength.

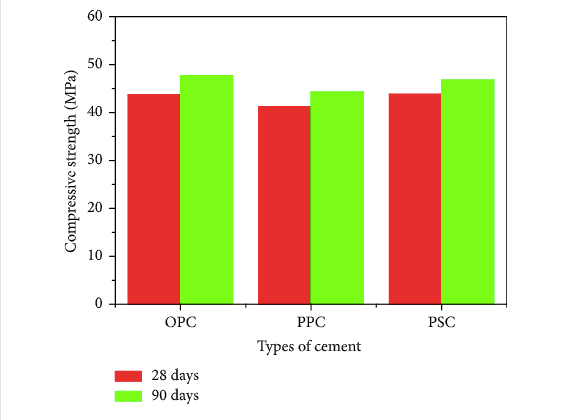

The comparative compressive strength bar chart of different types of cement.

Properties of cement:

There are two basic properties of cement:

- Physical properties.

- Chemical properties.

Physical properties:

Fineness: Reaction between the water and cement takes place at the surface, greater the surfaces greater will be the hydration and the strength of cement.

Hydration: When water reacts with the cement, heat releases, and the process is known as hydration of the cement. It adds strength to the binding material. In hot conditions dissipations of heat can cause several shocks.

Setting of cement: The time taken in the hardening process which is accountable for its strength known as the setting time of the cement and the process itself is called the setting of the cement. It is affected by the cement fineness and cement-water ratio and several other factors.

Soundness of Cement: The ability of the cement to resist the shrink after the hardening is known as the soundness of cement. Good quality cement must possess this characteristic so it can retain its volume after the setting.

Strength of cement: There are three types of strength of cement that are measured – compressive, tensile, and flexural. It depends upon several factors like water-cement ratio, cement-fine aggregate ratio, curing conditions.

Specific Gravity of Cement:

The specific gravity of cement= weight of a given volume of cement/ weight of an equal volume of water. Portland cement has a specific gravity of 3.15.

Chemical properties:

The chemical properties of the cement depend upon the ingredients used which have been already described in the above section.

Functions of cement:

- Cement is used to prepare the mortar.

- Cement is used to prepare the concrete.

- Uses as the binding material.

- Uses for the construction of cement concert roads.

- Can be used as fire-resistant.

- Cement is used in the building of significant engineering constructions such as bridges, culverts, dams, tunnels, lighthouses.

- Can be used as fire-resistant by adding suitable admixture to it.

- Cement is castoff for creating joints for drains and pipes.

- Cement can be used for the preparation of the foundations.

- It is used to harden the surface- to protect against the different atmospheric conditions.

Testing of Cement :

Laboratory tests of cement :

- Strength Test

- Fineness Test

- Setting Time Test

- Standard Consistency Test

- Heat of Hydration Test

- Soundness Test

- Tensile Strength Test

- Chemical Composition Test

Field Tests of cement :

- A good cement should not contain any visible lumps.

- The Colour of the best cement should be greenish-grey.

- If you thrust your hand into the cement bag then you will get a cool feeling.

- When you pinch cement and feel-between the fingers, it should be smooth.

- Take some cement and throw it on a bucket full of water, For good cement, the particles should float for some time before they sink.

Cement is the best binding material with a long history of use in the construction industry. Its various types make it useable under different conditions. Different types are available so one can select them according to his/her requirements.

Please share this article to support us! Thank you.

[epcl_box type=”information”]References:[/epcl_box]

- https://standards.globalspec.com/std/13208545/BS%20EN%20197-1

- https://www.britannica.com/technology/cement-building-material

- grade of cement

- Sidney Mindess & J. Francis Young (1981): Concrete, Prentice-Hall, Inc., Englewood Cliffs, NJ, pp. 671.

- Steve Kosmatka & William Panarese (1988): Design and Control of Concrete Mixes, Portland Cement Association, Skokie, Ill. pp. 205.

- Velu Saraswathy, Subbiah Karthick, Han Seung Lee, Seung-Jun Kwon, Hyun-Min Yang, “Comparative Study of Strength and Corrosion Resistant Properties of Plain and Blended Cement Concrete Types”, Advances in Materials Science and Engineering, vol. 2017, Article ID 9454982, 14 pages, 2017. https://doi.org/10.1155/2017/9454982